| 5 Axis Desktop CNC Electronics |  |

|

|

|

|

|

|

|

| A 5 axis desktop CNC control electronics.

|

|

|

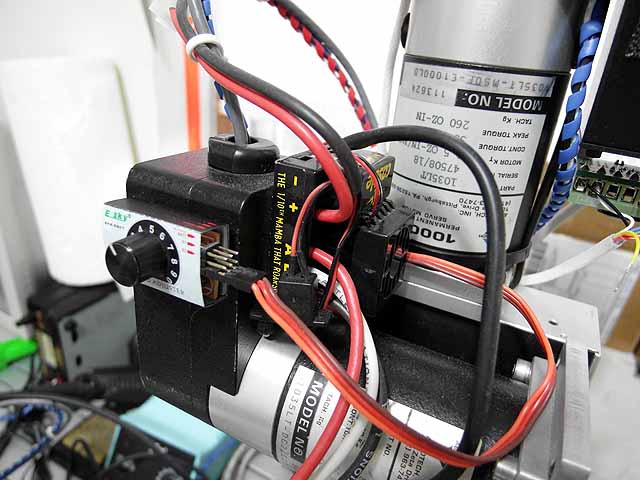

Geckodrive G320X servo drive (3/09/2010) Geckodrive G320X servo controller One potential servo drive evaluated for use. The Gecko is a very compact drive, with a professionally constructed enclosure.

|

|

Whale3 servo drive (5/16/2010) Whale3 servo controller 5 whale3 servo drives will be used to control the mill. Whale3 drives were chosen over the Gecko320X due to the advantages of a USB interface for computer controlled tuning, the ability to hold servo position without dithering between encoder counts, higher encoder supply current, and lower cost. |

|

Whale3 servo drive stack (6/25/2010) Set of 5 whale3servo drives. |

|

Servo drive mounting plate (7/31/2010) Mounting plate for servo drives.

|

|

Servo drive stack (7/31/2010) Servo drives bolted to mounting plate.

|

|

Servo drive stack (7/31/2010) Servo drive mounting plate bolted to mill and connected to 24V 16.6A switching power supply.

|

|

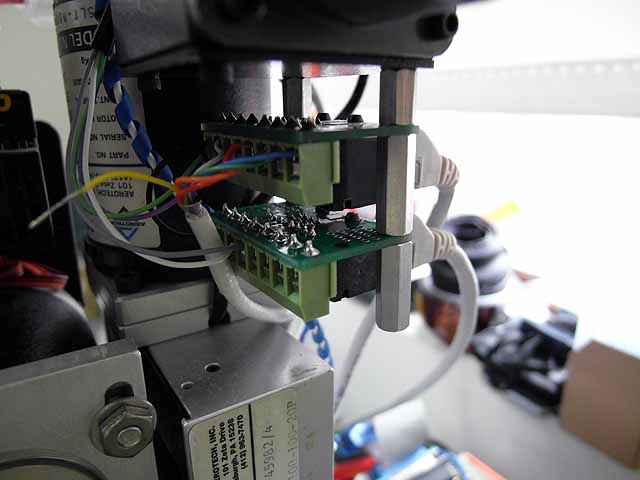

Servo drive control breakout (6/18/2011) DC-DC converter to supply 12v to the servo drive logic, and parallel to RJ-54 breakout stack.

|

|

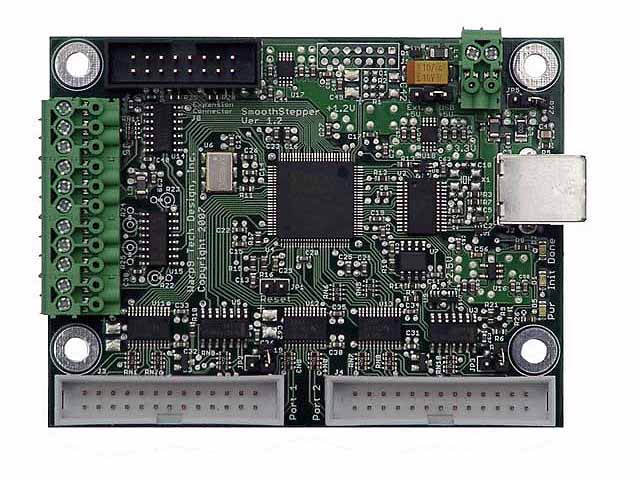

Smoothstepper motion controller (6/25/2010) Smoothstepper motion controller Motion controller is run with Mach3 through a USB port and provides step/dir signals to the whale 3 servo drives. |

|

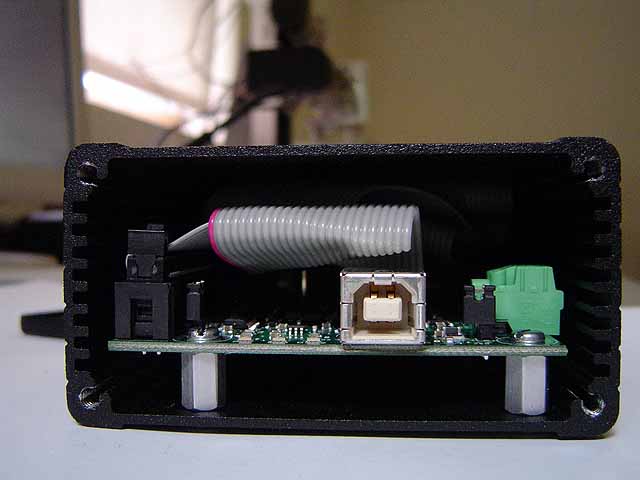

Smoothstepper motion controller (6/25/2010) Mounted in metal box. |

|

Smoothstepper motion controller (6/25/2010) Box front. |

|

Smoothstepper motion controller (6/25/2010) Box back. |

|

Manual control box (6/18/2011) Provides start, hold, estop input buttons.

|

|

Spindle power supply (6/18/2011) 12V switch mode power supply for spindle power |

|

Spindle speed controller (6/18/2011) RC car brushless motor controller and servo PWM generator.

|

|

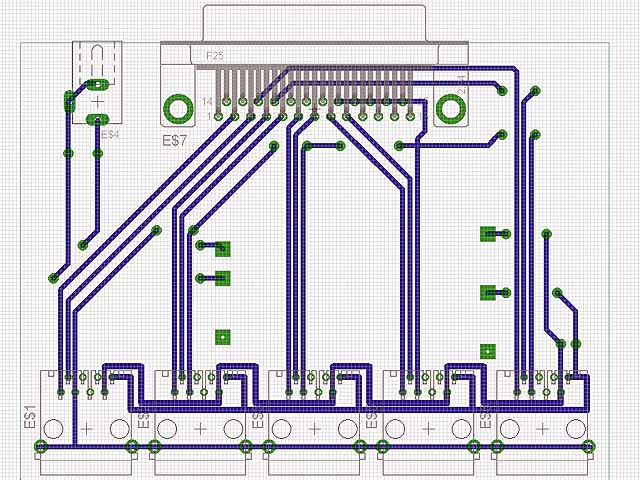

Servo control breakout (7/04/2011) Board design in Eagle. |

|

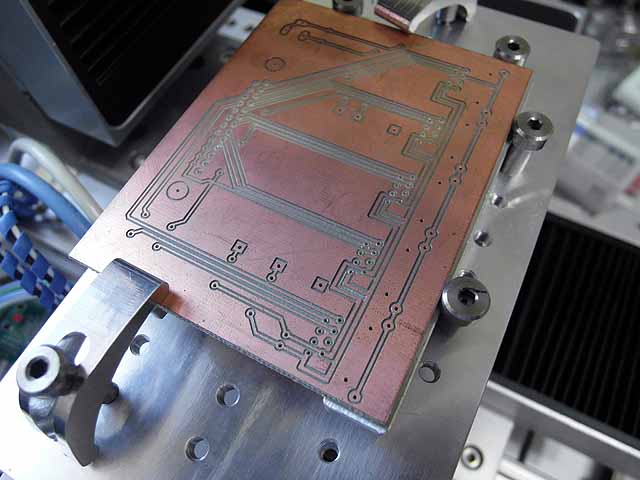

Servo control breakout (7/04/2011) Board after milling and drilling. |

|

Servo control breakout (7/04/2011) Board with holes drilled to size and components soldered in. |

|

Servo control breakout (7/04/2011) DC-DC converter mounted.

|

|

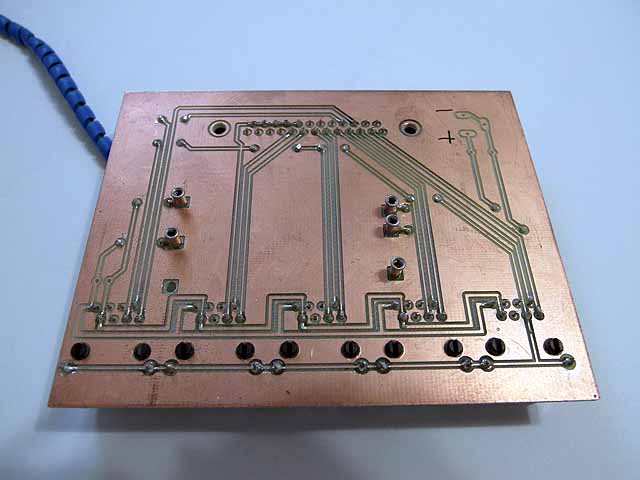

Servo control breakout (7/04/2011) Board top. |

|

Servo control breakout (7/04/2011) Board mounted on CNC |

|

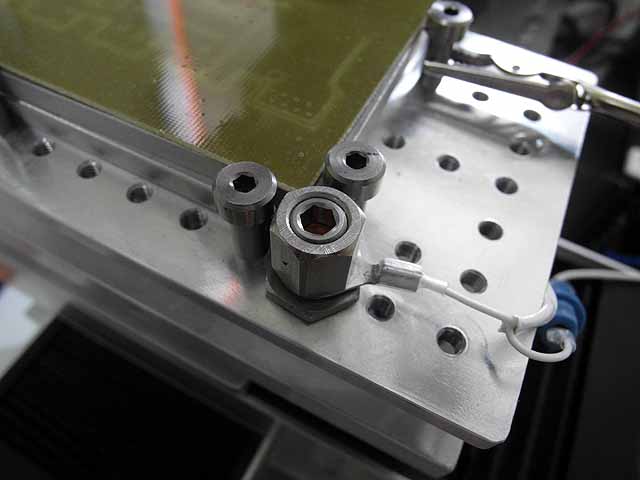

Optical limit switch connector (9/05/2011) Aerotech stages have built in optical limit switches. These are powered off the 5V encoder supply and converted to an RJ45 jack. |

|

Optical limit switch breakout(9/05/2011) Temporary breakout connecting optical limit switches to DB25 ribbon cable. |

|

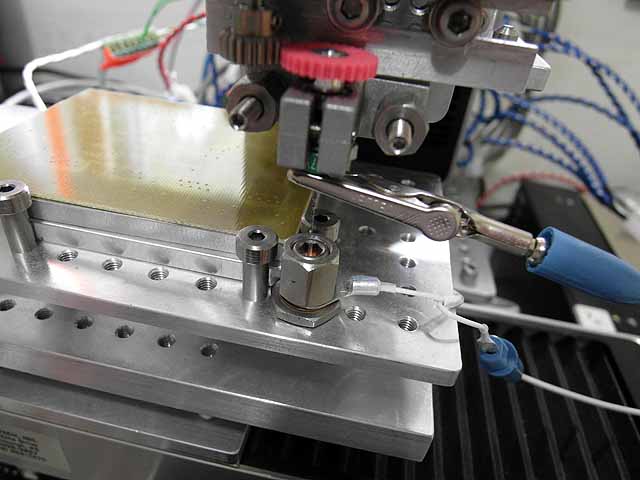

Automatic tool setter (9/05/2011) Automatic tool setter for CNC mill. Components: 10-32 insulating stud, tool setter body, spring, copper contact disk, retaining collar. |

|

Automatic tool setter (9/05/2011) Electrical connection to controller and alligator clip to connect to mill bit. |

|

Automatic tool setter (9/05/2011) Bit in position for zeroing with alligator clip attached. |

|

|

|

|

By attempting to reproduce any experiments or devices listed on this domain in part or in whole, you agree to hold me harmless against any lawsuit or liability. Copyright © 1998 - 2013 by Andrew Seltzman. All rights reserved. |

|

| Contact me at: admin@rtftechnologies.org | |